- What new appreciations did you develop while working as an intern? Why?

I started to appreciate engineers as a whole. The men and women who choose to work as engineers have to go through back-breaking work for the betterment of society. Because of engineer's work, they create new mechanisms, tools, and machines. - What qualities or characteristics did you see in the people around you that you want to develop in yourself? Why?

Engineering knowledge. I would like to be able to develop the knowledge to be able to talk to an engineer fluently, about concepts and ideas in the world of engineering.

- How was your work as an intern meaningful to your education?

I have learned about practical engineering skills such as wire basics, chemical procedures, and different tools. The skills I have learned in high school such as soldering and powertools have definitely prepared me for my education in and beyond college. These skills are also transferable across different fields of engineering.

What did you learn about your own work from your internship project? While working, my obsessive-compulsive side tends to show. During internship, I learned a lot about my work ethic concerning my OCD side. When I was cleaning linear blocks, I was putting out 110%; I was making completely sure to do the best job possible. I also felt like I was a part of the company, and so I made sure to complete all my jobs as if I worked there.

How has this experience (the internship) made you consider your college path that will ultimately lead to your career? Truthfully, the practical engineering skills I have learned at my internship (wiring basics, dealing with different chemicals and tools, etc.) have been very meaningful towards my education. This will also be extremely meaningful towards and beyond college. Because I become obsessive-compulsive during work-related experience, I've cleared up any doubts about Engineering being the correct career path for me.

I have carefully observed and learned about my mentor and other employees at Kramer Engineering, and I have reflected on my own academic and professional preparation. The internship position I am in right now has inspired me to strive to become an Engineer! My college path has been firmly decided, and I will ultimately become an Engineer.

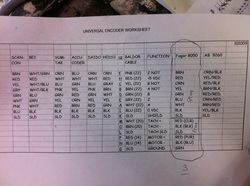

This week in the parts dept. I was given the nifty task of wiring different sections of the old scrap router. As you can see, the Fagor 8000 column is circled on the paper. Fagor is a company that (to my knowledge) sends parts in to the parts dept. for repairs, just like the other clients. This wiring pattern under the Fagor 8000 column connects to a specific part on the router. In fact, each column on the paper connects to a different section! 10 wiring jobs in total.

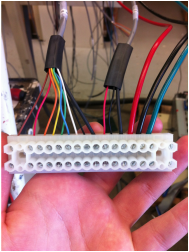

After about an hour of getting to grips with the basics of wiring, this is the final product.

I had to cut, strip, position, and clamp down each individual wire that leads into the white component (I still don't know what it's called)! Quite the gruesome labor, as I ended up chafing the sides of my thumb and forefinger whilst twisting the wire.

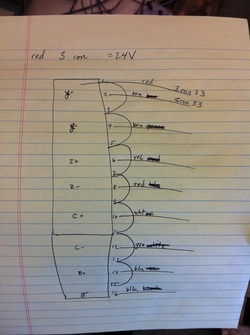

These wiring jobs were great sources of learning and anxiety. This piece of paper details how I should wire my next section. In addition, this wiring job required that I had to loop a red wire back through every other hole. In every other hole(offset from the red wire), a different colored wire is supposed to be placed. Notice that this is fairly similar to the universal decoder worksheet above.

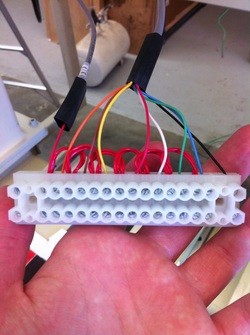

After a day of "action packed" wiring, this is the final product. As you can see, the wires are organized in a similar fashion as the other picture. This is because there is a universal code- a mantra- for engineers, relating to wire order. BRN, RED, ORN, YEL, GRN, BLU, WHT, BLK, S=LD.

Of course, it will differ with each and every item you particularly decide to wire. In this case, the BRN wire is switched with the RED wire. The SLD mentioned above stands for shield. The SLD wire is wrapped around the other wires, encased in a special foil. The purpose of the SLD is to shield the other wires from sound; as sound can damage and interfere with signal.

Siale is my "afternoon mentor". After everyone starts shuffling out of the office in the afternoon, I usually find my way into Siale's office. In these last hours of the workday, I help Siale with a new project and I learn new skills because of it. This week, I worked with the soldering iron to rebuild small battery packs. More about this task can be read below.

The process of rebuilding battery packs is a simple one. I begin by unscrewing two screws from the battery pack box. Next, I pull the circuit board out of the box. I use needle-nose pliers to rip off hot glue- this was holding the inoperative battery in place. Thirdly, I cut the soldering that was holding the inoperative battery in place, and begin removing the solder. This process is particularly annoying.

Next, I place the new battery on the circuit board, and solder it into place. I affix the battery pack box onto the circuit board and screw the screws back into their respective holes.

The reconstruction process is nearly complete. In the final step, I use a multimeter to test whether the battery pack outputs the correct voltage. I turn on the multimeter by turning the dial to V(with an M shape hovering above) to select volts. Placing the red(+) test lead on the farthest left pin, and the black(-) test lead on the next pin to the right will give me the correct current. The batteries are supposed to output 36.6 volts. As you can see, the multimeter is displaying the correct amount of voltage. The procedure is complete.

Have you advocated for yourself during your internship, or seen advocacy demonstrated in other situations?

Every day at my internship, I ask questions whenever possible. Internship is a learning experience, after all. Although I work on linear guides every day, I am still able to learn/ work on other projects- this gives me a lot of invaluable source of experience.

Many-a-time I have asserted my interests while talking with my colleagues. This allows them to understand more about what I hope to get out of my time at Kramer Engineering.

Additionally, when I have nothing to do, I ask around if there is any work I could be of assistance with. I recognize that as an intern, I should be offering myself as help as much as possible. it makes everyone's life easier at the workplace.

This large hunk of 1/2" steel columns, plates, and beams is called a router- otherwise known as a CNC machine. This particular router is my timely "pet project" for the time I will be working at CNC Parts Dept.

To a fresh pair of eyes like yours, this router looks fine and dandy. To a hardened engineer, this router looks like absolute garbage! Why? Because it was build out of scrap parts in someone's garage. I will be helping to refurbish this Frankenstein of a CNC.

My makeshift workbench is accompanied by top-of-the line gear. This includes screwdrivers of assorted sized, needle-nose pliers, a wrench, some Multi-Purpose Lithium Grease, Mineral Spirits, and some cups.

With these tools, I am able to work on my side project or fixing up old linear guides (also known as runner blocks). I will be selling these on my own in the future.

This is a closeup of a linear guide. From all the hours of work I have poured into cleaning these, I have gained much knowledge of the inner workings. As a matter of fact, it takes me an average of 3 hours to completely clean and rebuild a single runner block.

It takes many hours of troubleshooting whenever I completely reassemble a block and find out there is something causing the ball bearings to jam up. A long process ensues, and I end up taking an entire day learning more about linear guides.

Here, I am using a caliper to measure a 2.50 mm ball bearing. 2.50 is the standard size that is used in STAR brand linear guides. It is extremely important to remember that there are multiple sizes of ball bearings. This is often a very easy way to stop up a linear guide.

Trust me, the whole process of taking apart a linear guide and rebuilding it for another hour is not fun, especially if only one of your ball bearings is a different size.

I hold many odd-jobs around the company. These incude (but are not limited to):

-Linear guides

-Running errands

-Sweeping

-Cleaning things

-Filing (Very rare case scenario)

-Reaching for things others can't normally reach

Although my internship is filled with complexities, and hours of work involving router parts, I have no burning questions so far.

I have been learning skills as I work on various tasks- the implementations of everything I do are becoming apparent more and more each day.

If I were to ask a question, it would most likely be on wiring. Hos is the neutral wire similar and different when compared to the ground wire?

I heard from Sam earlier today that he was researching wire types. He found that ground wires and neutral wires are similar, but he couldn't find any differentiation's.

Here at Kramer Engineering, there are several skills required in order to become "one" with the engineering. So far, I have been able to not only learn, but refine my skills useful to the company.

1. Cleaning: I have become an articulate cleaner over the past few days. Having to prepare an entire CNC machine for painting is no laughing matter. It took approximately 7 hours to almost-fully clean the entire hulk of machinery. In fact, I was on the top ring of a ladder for an entire work day with a more than a few rags, and a bottle of Natural Blue.

2. Tools: Ever since my first day at the parts department, I have learned about a plethora of tools that engineers use in their every day lives. To my astonishment, I was even able to find in Siale's office, a giant 2 foot long wrench! I didn't even know wrenches could become that large.

3. Independence: By far the most important thing I have used in this internship is independence. I have walked into the parts department every morning, said my "good mornings", and started working on my recent project without even the slightest amount of babysitting required. This is a huge step from what I remember happening at high school between teachers and students. This step has taken me in the right direction.

Before I get along to the blog post, I would like to apologize for posting this late (this is in response to the last post policy). I thought I had initially published my post on Friday, but it slipped my mind!

My experience at Kramer Engineering has been an amazing one! The workplace is absolutely striking in the fact that I am able to be around things that I am truly interested in. My overall impression is that there is going to be a lot of work for me to do; this includes refurbishing a CNC machine, learning about CNC aspects and components, and cleaning and understanding the structure of Linear guides.

My colleagues are an awesome bunch!

-Lynn is the general manager and my mentor.

-Angus is the man who controls and forsees all communications over telephone.

-Siale is the tinkerer, and overall master of the packaging room.

-Sam is one of the Engineers. He is also an awesome guy to eat lunch with.

-Eric (who I haven't met yet) is Lynn's partner-in-crime.

I am definitely most excited about all the work I am going to be able to complete and show for my deliverable. This internship is going to give me a lot of valuable experience that I could otherwise not do without!

Hello!

Just a few weeks ago, I was able to commute to Kramer Engineering to conduct a friendly interview with my mentor.

According to Lynn Kramer, at CNC, there a calls being taken and made. Customers are usually broken down - sometimes they know what is wrong with their machine and sometimes it needs to be figured out.

In order to work a normal day at Kramer Engineering, several skills are required:

- Multitasking

- Motor Repair and Assembly

- Purchasing parts that customers need in a hurry

- Selling whole machines

Kramer Engineering is classified as a Lifestyle company. "Employees choose their own hours, but are required to stick with those hours. A person's pay range directly reflects quality and whether the schedule can be maintained." Lynn Kramer

The Dress code is as follows:

- Close toed shoes

- Shirt, pants, etc.

- Masks and safety goggles are provided

Many of the employees backgrounds are related to mechanical engineering, as well as business.

Lynn in specific worked in the engineering department of a composites factory. She learned process, CNC programming, and tool design, which helped her prepare for this job.

There's no such thing as a typical work day in the Kramer Engineering Office.

"No Typical days! A typical workday is starting on a new project, then being interrupted by another project, then somehow finishing those all before the end of the day."

Lynn Kramer

|